Design for Repair

Exploration

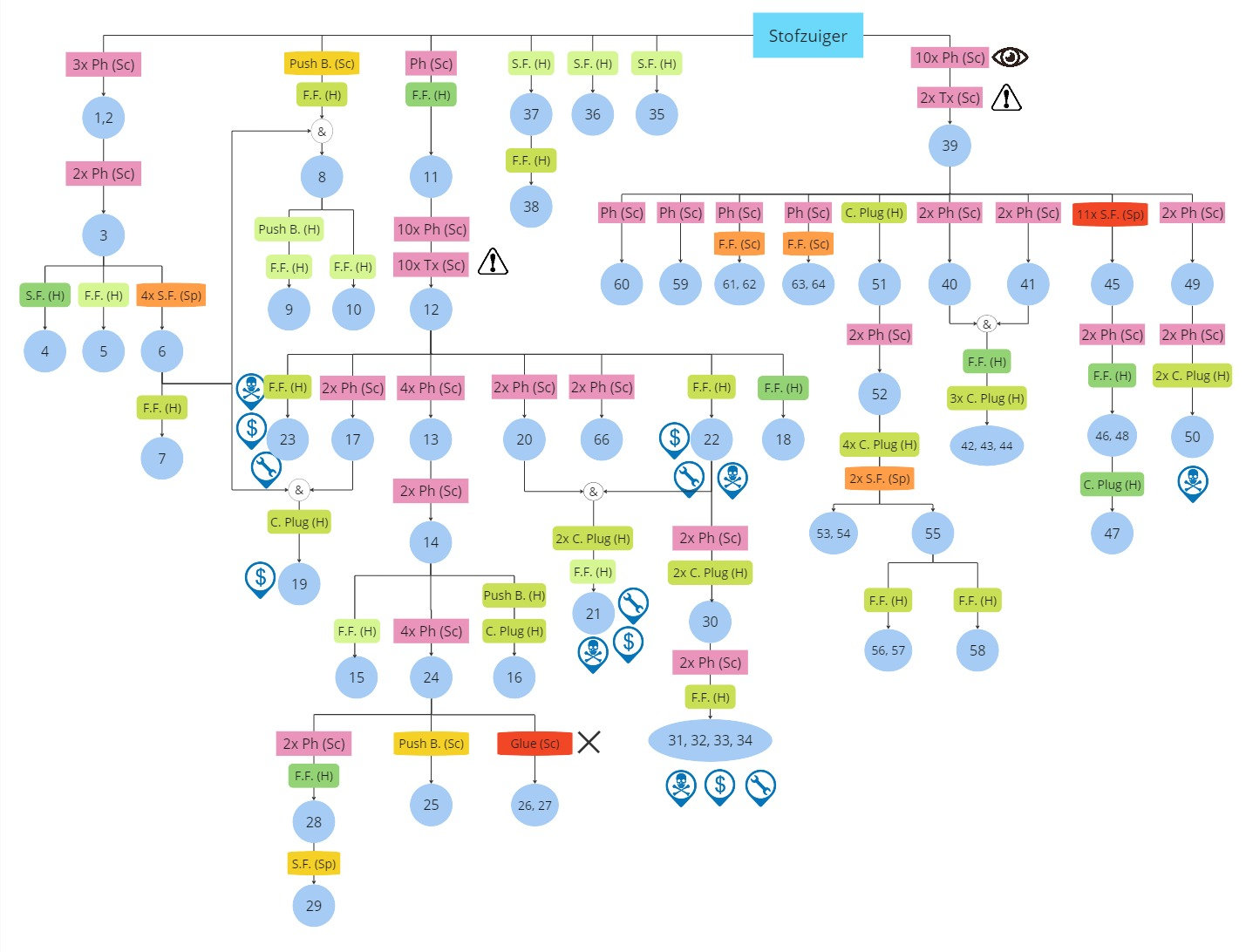

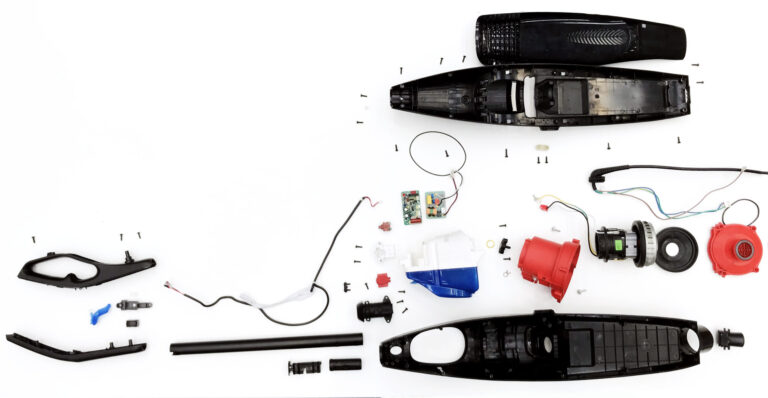

This study focuses on improving product repairability and sustainability through a case study of the Vileda JetClean vacuum cleaner. The product was analysed using a disassembly map to identify high-priority parts—components that need to be accessed quickly, either because they are prone to failure or valuable for recycling at the end of the product’s life cycle. Based on these insights, several redesigns were proposed to simplify the (dis)assembly process, creating a flatter and more accessible product architecture. The exploration also incorporates improved user guidance for repair, taking into account changing EU regulations on consumer self-repair.