Okki Nokki GO! redesign

Project

Redesigned in collaboration with Okki Nokki, the Okki Nokki GO! is a compact, automated record cleaning machine that delivers professional-level care in an intuitive and trustworthy way—essential for handling fragile items with strong emotional value. Users simply place a record, press the lid, and the machine completes the entire cleaning cycle: wetting, brushing, vacuuming, and drying, with subtle LED feedback providing guidance. Tailored to a new generation of vinyl enthusiasts, the updated design is lighter, more affordable, and easier to use than the original, offering high-quality record cleaning in a more accessible and user-friendly form, without compromising performance or care.

How does it work?

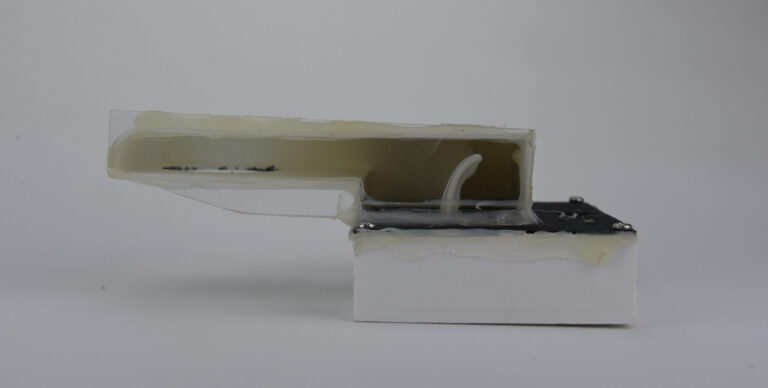

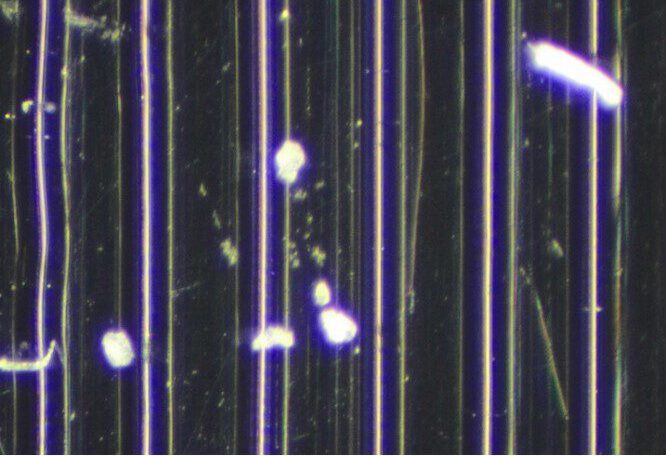

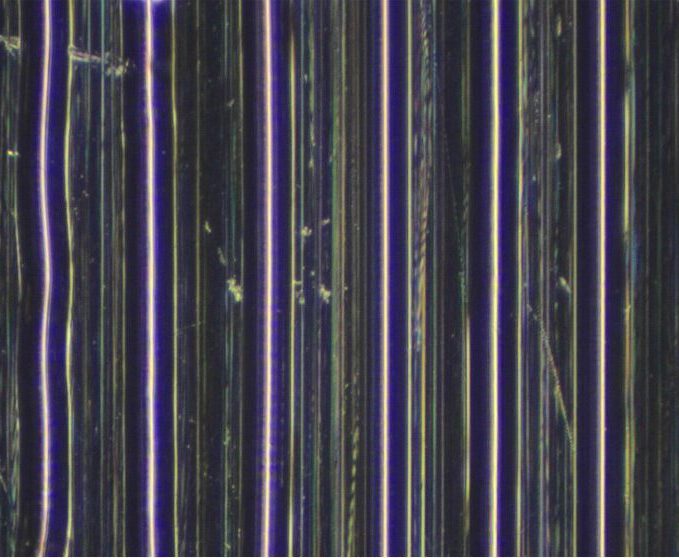

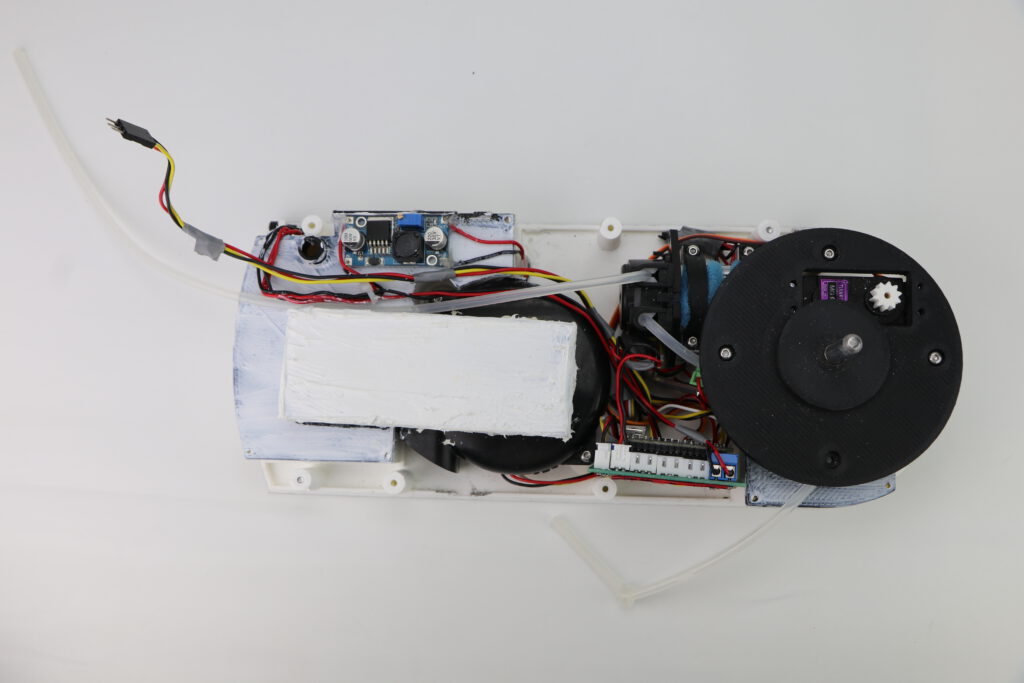

First, the user fills the internal reservoir with cleaning fluid and places a vinyl record onto the machine using the shell’s guiding lines. When the lid is closed, it seals the record label and triggers the automated cleaning cycle. A pump dispenses fluid onto the rotating record, which is then spread into the grooves by a velvet brush. Next, a vacuum system extracts the fluid along with any dissolved dirt, effectively drying the record. Built-in sensors verify that the lid is closed and a record is loaded before starting, while LEDs provide the user with status updates throughout the process. After cleaning, the lid opens automatically for easy record removal. The used fluid is collected in a separate container, which can be manually emptied.

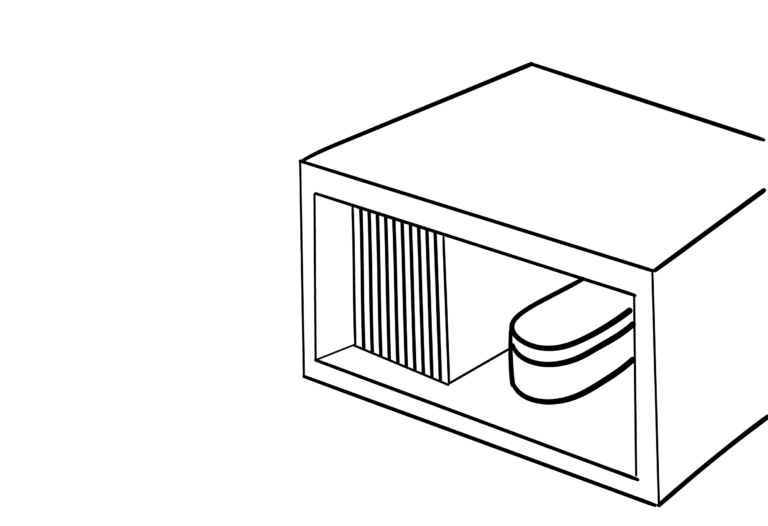

1

The machine is stored, meant to be part of the interior.

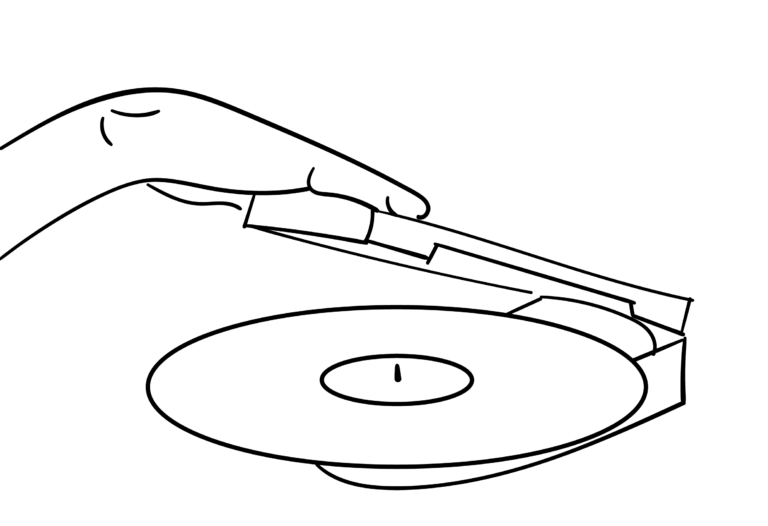

2

Records are handled with care, preserving the precious item.

3

The machine cleans automatically, meaning it wets, brushes, and vacuums the record.

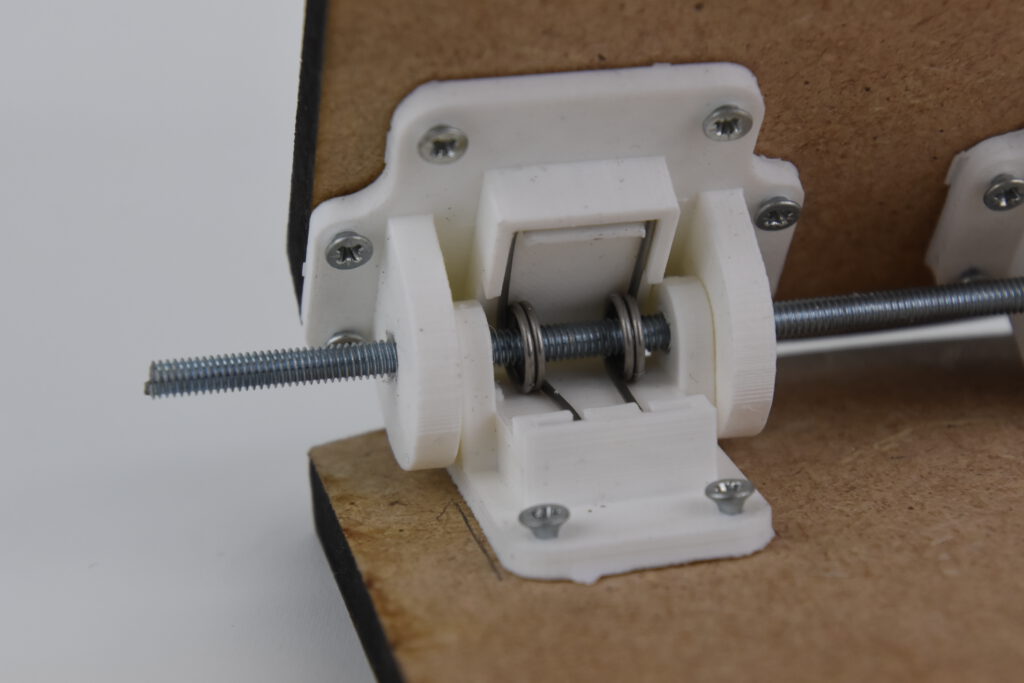

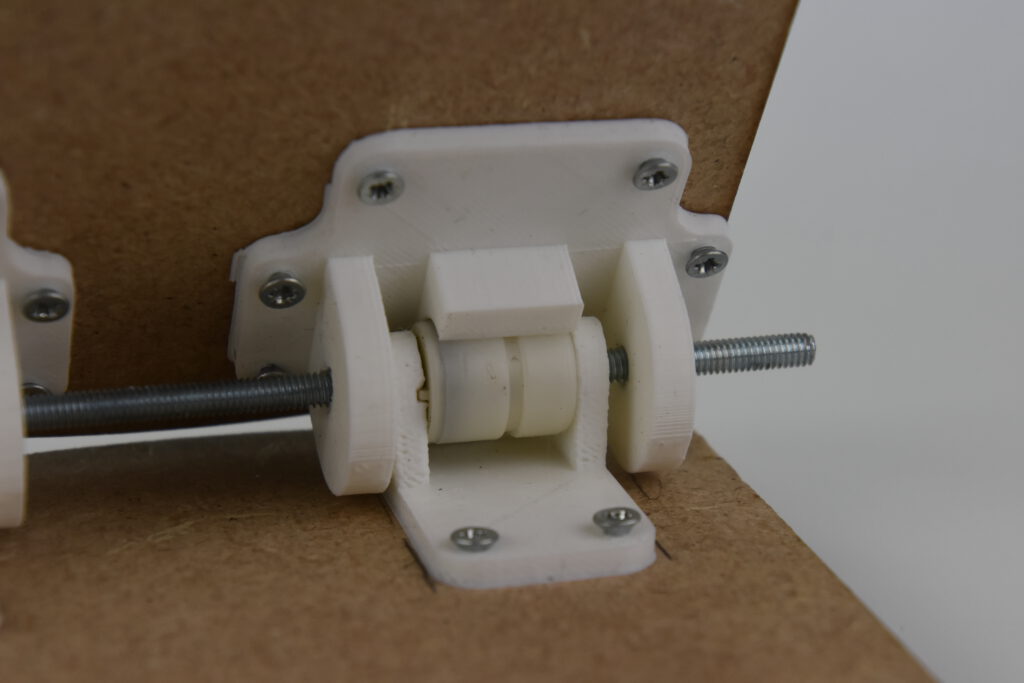

Required engineering

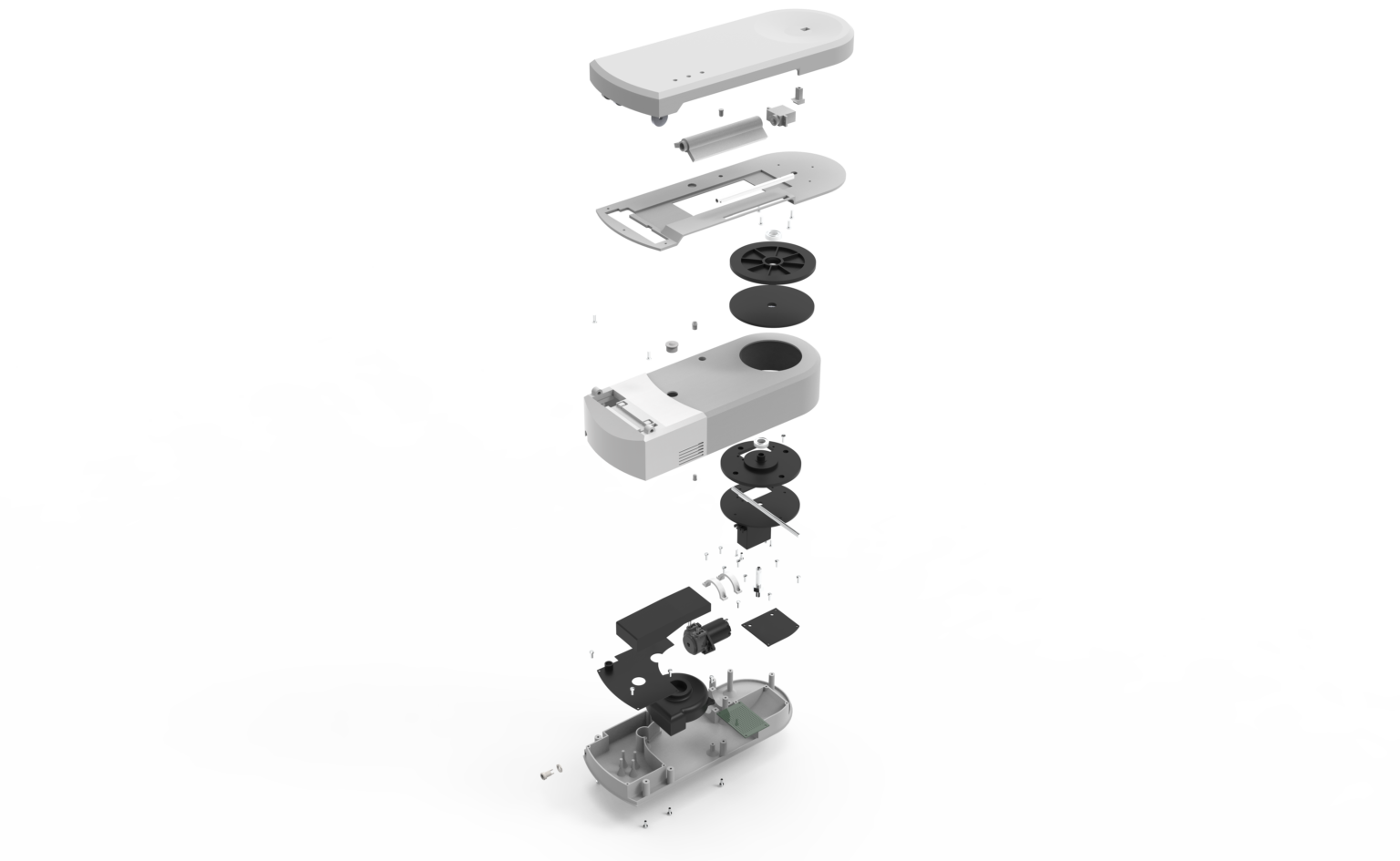

A thorough analysis of the target group revealed five key priorities that informed the redesign: trustworthiness, controllability, repairability, functionality, and affordability. Rooted in the practical, physical domain—and combined with the client’s goal of a fully functional prototype—these priorities steered the project into a technically demanding direction. CAD modeling, mechanical detailing, and hands-on work with electronics were essential to translate user-centered insights into a tangible, working solution.

Consumer product

As a product aimed at individual consumers—and with the client’s commercial goals in mind—cost price played a significant role throughout the development. This led to trade-offs, for example in electronics, where choices had to balance performance and affordability. Practical and financial considerations strongly influenced the design process, making efficient internal architecture a key priority. The product was divided into several subsystems, each developed iteratively and in parallel.